Fiber Laser Machinery Quantum Efficiency

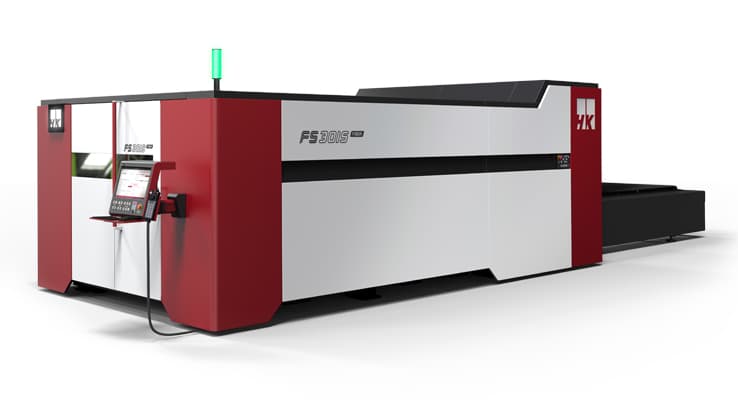

Dual-purpose fiber laser cutting machine is a commercial laser cutter system with dual functions to cut sheet metals, metal plates, metal tube, and metal pipes of steel, aluminum, alloy, titanium, copper, brass, iron, and other metal materials.

You can upgrade your machine with accessories such as a fume extractor or lenses.